Modum Safety

“Modum” is a biodegradable fire-and-explosion-proof compound belonging to the class of low-hazard compounds (the aqueous ready-to-use fluid has a concentration of from 0.1 to 2%, pH=7.0–7.2), which is absolutely safe for both humans and the environment.

EAfter use, ready-to-use “Modum” fluid can be disposed of in the usual way.

FIELDS OF APPLICATION

О TR MODUM

MODUM is a next generation technical cleanser.

We find ourselves in times in which Greta Thunberg calls out for an end of the environmental pollution in front of the UN Conference - no she’s even demanding it. At a time when "green" parties are gaining more and more support in all countries, it seems that humanity is only now beginning to care and protect its environment.

However, researchers were looking for solutions to solve this problem already for a long time, even if it’s were not as acute as today.

They understood early the more the industrial production progresses, more "dirt" and contaminants would naturally be created, which could not be cleaned without the use of various acids and aggressive detergents. And on top, the production and usage of those agents stresses and pollute our nature as much as carbon dioxide emissions does.

The Cold War reigned over the world, but solutions were sought on both sides of the Iron Curtain. Thus, in 1983, the scientist Valery Legasov was appointed head of the Department of Radiochemistry and Chemical Technology at Lomonosov University in Moscow. Under his supervision numerous methods, to improve the properties of various chemical compounds with the help of nuclear physics methods of synthesis, were developed and research into these new compounds began.

After the tragic death of the scientist in 1988, some of this work was shut down unfortunately and a follow-up funding to continue the research of many of these methods was excluded. Among them there was one that developed specially treated water, with influence of catalysts, that resulted in a product with strengthened properties.

Over the course of time, Legasovs’ followers and students, including ethnic Germans among them living in the Volga region, continued to work on the creation of unique cleaning agents in numerous scientific institutions in Russia. As a result, several excellent detergents were created, which were successfully used in the Russian industry. For 17 years, experiments and trials have been conducted to improve the properties of these detergents. Now, in our time, in modern Russia, a team of scientists and engineers had been able to collect the experience of all these scientific institutions and bring it together. As a result of these scientific researches a composition was created which is the basis for the unique detergent "MODUM".

Now the time has come to prove its exclusivity on the German and European market. In contrast to conventional cleaners, "MODUM" is, apart from its excellent cleaning effect, absolutely safe for humans and their environment.

Operating manual TR MODUM

MODUM is a next generation technical cleanser.

Intended purpose:

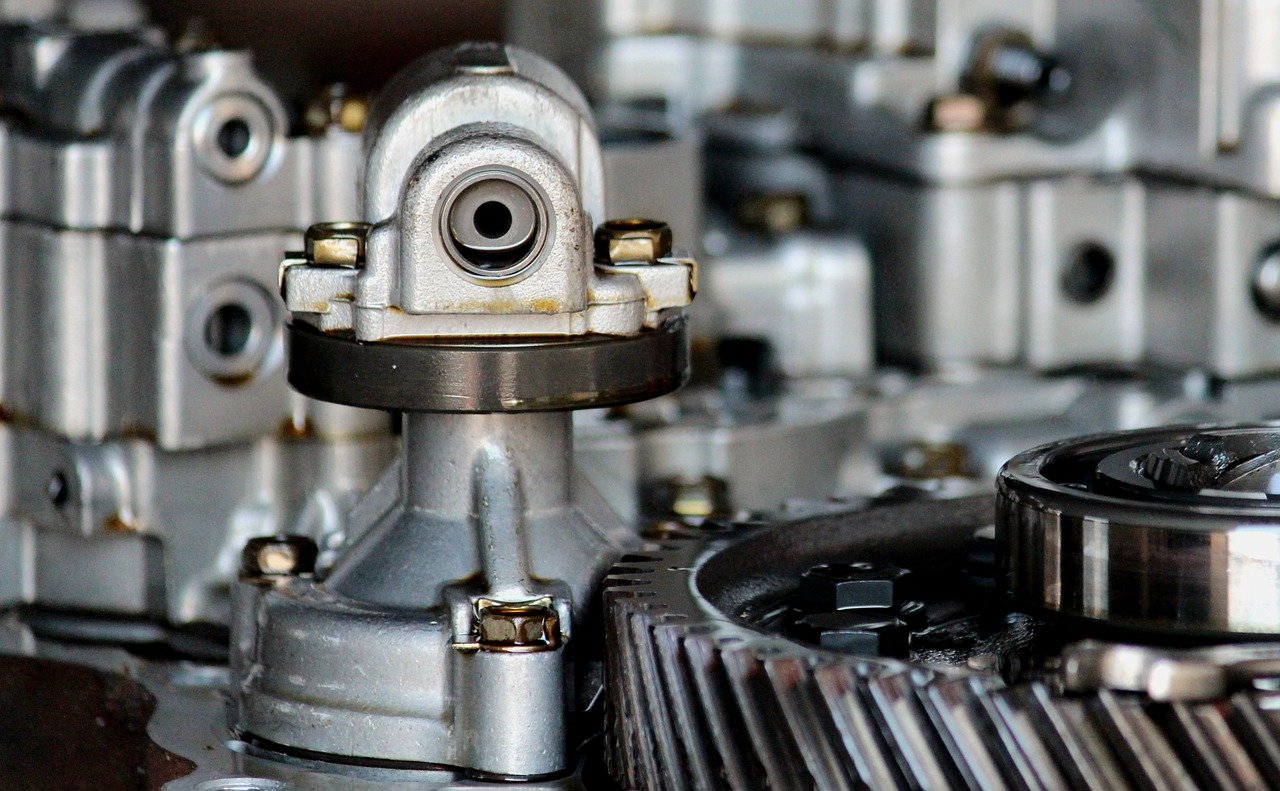

- degreasing of all metals before pending repair, galvanization, coating or painting;

- washing of metals after mechanical treatment;

- cleaning and degreasing of polymer materials;

- soil cleaning of salts and oil products;

- degreasing of fur and skins;

- washing and maintenance of equipment in industrial plants;

- washing of glass and optical elements.

Production of a working fluid:

Requirements for the preparation of a fluid: Measuring cup, water thermometer and an empty container for the ready-to-use fluid.

The MODUM working fluid is prepared in a ratio of 1 litre of MODUM concentrate to 50 litres of water. The water temperature for the preparation of the solution should not be lower than 30 degrees.

Before assembly, galvanizing or coating with paint the fluid concentration can vary between 1:30 and 1:100 depending on the degree of surface contamination.

After production, the solution must be mixed thoroughly.

Working temperature of the fluid: from 5 to 100 degrees.

The fluids are prepared according to requirements and their durability are considered.

Correction / adaptation of a working solution:

The fluid is functional and ready-to-use over a long period of time and does not require any correction.

If necessary, the adjustment is carried out with water only.

Application:

MODUM is to be used as follows:

- manually, by household means;

- with a high-pressure washer;

- in various types of washing machines.

The optimum result of MODUM is achieved by using high pressure jet washing.

In case of highly contaminated metal surfaces, it is recommended to increase the concentration of the working fluid and use a jet washer.

For the treatment of large-sized parts it is recommended to use the fluid in water jet washing machines with heated water and a solution tank.

MODUM is also suitable for passivation of parts. To ensure protection, it is necessary to dry the workpiece with hot air in prior. In machines with water heating the passivation is done automatically. Under storage conditions the passivation effect is maintained for approx. 40 days.

A reduced consumption of the cleaner is achieved in washing machines by repeated use of the fluid. In this case, all contaminants are filtered out in a special tank by filters usually installed in such plants before a new reuse cycle.

The long-term purity of the solution is guaranteed by the separating / splitting properties (demulsifier). Oil contaminants are broken down and visibly separated within the solution so that they can be easily removed.

Storage:

MODUM is stored in tightly closed plastic containers.

Transportation:

There are no restrictions on transport of MODUM.

Composition:

Emulsion consisting of an optimized combination of non-ionic surfactants (NSABs), inorganic salts and other active additives.

pH value: ~ 9.1.

Mass fraction of free alkali during conversion to NaOH and other mechanical impurities ~ 0.07 - 0.1%.

Durability:

24 months from date of manufacture.

DESCRIPTION OF THETR MODUM

MODUM is a next generation technical cleanser.

MODUM is a universal, highly concentrated agent for cleaning and degreasing of various surfaces. However, the product is not a solvent. The chains of hydrocarbon compounds are being destroyed at molecular level, therefore organic impurities are removed. Yet it doesn’t react aggressive on the surfaces of the parts being washed or on the equipment in which the product is used.

The range of applications is widely spread. It can be used in mechanical engineering, aviation, metallurgy, petroleum, agricultural and food industry, in railway transport, tanneries, housing construction and municipal service providers, etc.

The application of MODUM can be performed manually or mechanized. A manual treatment includes working with a brush, or other improvised means, as well as with a high-pressure water jet. Mechanized methods include various types of washing equipment. There’s no need to change the design of the existing blasters in order to use MODUM, in equipment or plants with closed circuits.

Due to its demulsifying features MODUM is the perfect tool for utilization in closed circuit washing plants. All from the surface removed contaminants are expelled to the solutions’ surface and can be easily filtered out.

The top oil layer deposited on the solutions’ surface is clearly visible, which makes it easy to remove it manually from the surface.

Due to the corrosion inhibitor it contains, MODUM enables the passivation of metal surfaces simultaneously during the washing process.

MODUM is a product of the latest generation and is considered as a low hazard compound. It is completely water-soluble, non-inflammable, non-toxic, free of abrasive particles and carcinogens, completely biodegradable and the pH-value is harmless in case of skin contact.

PROPERTIES OF THE TECHNICAL CLEANING AGENTTR MODUM

MODUM is a next generation technical cleanser.

- High degree of cleaning and degreasing;

- Environmental friendly;

- Biodegradable;

- Completely soluble in water;

- Non-flammable;

- Free of carcinogens or toxins;

- No free alkalis or other aggressive components contained;

- Free of abrasive particles;

- Does not harm metal surfaces;

- Can be used at relatively low temperatures (from +5 °C);

- Does not require special disposal;

- Safe operation;

- Does not require the use of protective equipment;

- Guarantee of long-term purity of the working fluid due to demulsifier features;

- Corrosion inhibitor - protection against corrosion for about 42 days when stored in warehouses;

- Antistatic effect;

- Active water softener;

- Oil displacer - Increases oil production;

- Cleans surfaces of all types of metals before repair, defects, galvanization or coating with paint;

- Cleans surfaces of metal parts after processing / machining;

- Washing and degreasing of large-sized parts possible;

- Cleaning of polishing compounds after polishing;

- Cleaning of any kind of polymer coatings;

- No harmful effect on anode coating when processing aluminium surfaces;

- Ground and soil cleaning of salt and oil products after an environmental disaster or oil spillages;

- Washing of optical elements and glasses without dilution;

- Process acceleration of biodegradability.

APPLICATION EFFECTS OFTR MODUM

MODUM is a next generation technical cleanser.

- High washing effect of organic impurities;

- Anti-corrosion protection;

- No deposits, stains or contamination;

- No costly disposal of the working fluid;

- Easy-to-handle disposal of the remaining impurities;

- No special requirements for washing systems;

- Reduction of pollutant concentration in industrial plants;

- Use of mechanical auxiliaries not necessarily needed;

- Efficient water and working fluid consumption;

- Saving on power consumption;

- Increased employee productivity;

- Increased service life of facilities and equipment;

- Reduction of pollutant concentration in sewage systems;

- Application in fully automatic washing plants, equipped with filters that extract hydrocarbons from the air during the washing process;

- Accompanying degassing of oil tankers and oil storage facilities;

- Cleaning of used and concentrated galvanic solutions from heavy metal ions, manganese and nitrogen-ammonium compounds.